Types of Flattening Stones

Types of Flattening Stones

A flattening stone is also known as a lapping stone, lapping plate or leveling stone.

A flattening stone is typically used to level or flatten the surface of a sharpening stone. As a sharpening stone is used repeatedly, it tends to wear more in the middle of the stone than along the edges. If the sharpening stone is not kept flat your knives and tools will develop slightly rounded edges and become much less effective at cutting. To keep your stone flat you periodically lap it on the surface of the flattening stone.

There are two basic types of flattening stones that are commonly used.

Flattening stones are made out of either a solid block of silicon carbide or a meal plate with a diamond abrasive nickel plated to one surface. Regardless of the type of material they are made from, all flattening stones are made from a very coarse grit.

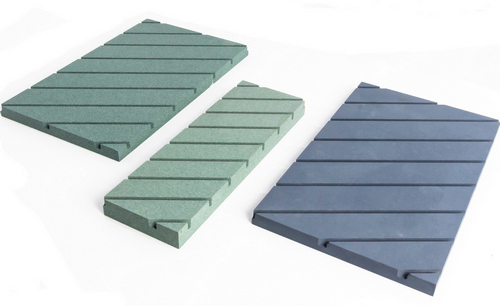

A flattening stone made from Silicon Carbide is much less expensive than a diamond lapping plate but they also wear much more quickly. The price range for a Silicone Carbide flattening stone is typically $20 - $50. Silicon Carbide stones are manufactured by companies such as Norton, Pride Abrasives, and others.

Both types of stones are used with a liberal amount of lubricant. The lubricant used varies depending on the type of sharpening stone that is being flattened. If you are flattening an oilstone you use oil as a lubricant and if you are flattening a water stone you use water.

Both types of stones are used with a liberal amount of lubricant. The lubricant used varies depending on the type of sharpening stone that is being flattened. If you are flattening an oilstone you use oil as a lubricant and if you are flattening a water stone you use water.

The process of using a flattening stone is pretty basic. Lubricate the flattening stone and simply rub the sharpening stone over the surface in either a circular or back and forth motion. Periodically check your sharpening stone for flatness using one of the methods discussed here. It is important to use plenty of lubricant. Flattening a water stone is best done next to a sink or better yet, under running water.

We always welcome feedback about our articles. For feedback, suggestions or comments please Contact Us.

To read more articles click here Articles

References:

Design Dimensioning and Tolerancing (Book) | Wilson, Bruce A., Goodheart-Willcox Pub

A flattening stone is also known as a lapping stone, lapping plate or leveling stone.

A flattening stone is typically used to level or flatten the surface of a sharpening stone. As a sharpening stone is used repeatedly, it tends to wear more in the middle of the stone than along the edges. If the sharpening stone is not kept flat your knives and tools will develop slightly rounded edges and become much less effective at cutting. To keep your stone flat you periodically lap it on the surface of the flattening stone.

There are two basic types of flattening stones that are commonly used.

Flattening stones are made out of either a solid block of silicon carbide or a meal plate with a diamond abrasive nickel plated to one surface. Regardless of the type of material they are made from, all flattening stones are made from a very coarse grit.

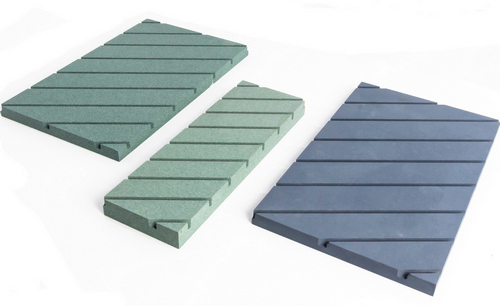

A flattening stone made from Silicon Carbide is much less expensive than a diamond lapping plate but they also wear much more quickly. The price range for a Silicone Carbide flattening stone is typically $20 - $50. Silicon Carbide stones are manufactured by companies such as Norton, Pride Abrasives, and others.

Silicone Carbide Flattening Stones

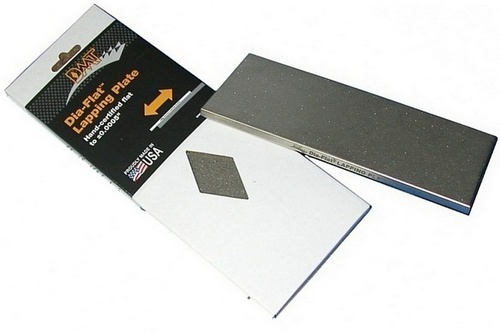

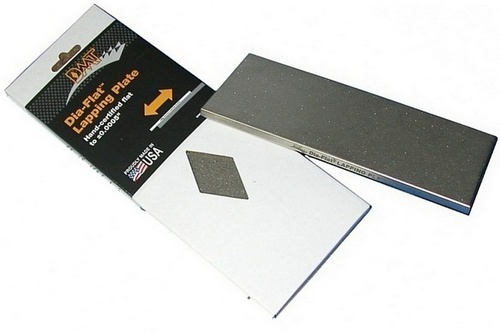

The price range for a quality diamond lapping plate ranges from just under $200 to over $350. The diamond lapping plate has two main advantages. It will flatten any type of sharpening stone you are working whether that be an oilstone or a water stone. Secondly, the diamond plate works much faster than a silicon carbide flattening stone. In addition, a diamond lapping plate will last much longer. The two most popular diamond lapping plates are the Shapton Lapping Plate and the DMT lapping Plate.

Diamond Lapping Plates

The process of using a flattening stone is pretty basic. Lubricate the flattening stone and simply rub the sharpening stone over the surface in either a circular or back and forth motion. Periodically check your sharpening stone for flatness using one of the methods discussed here. It is important to use plenty of lubricant. Flattening a water stone is best done next to a sink or better yet, under running water.

We always welcome feedback about our articles. For feedback, suggestions or comments please Contact Us.

To read more articles click here Articles

References:

Design Dimensioning and Tolerancing (Book) | Wilson, Bruce A., Goodheart-Willcox Pub